Copperweld

/About the company

Copperweld®’s story is one of American innovation and determination. Throughout their 100 plus years, the one constant has been their workforce- dedicated and determined, they are the heartbeat of Copperweld®.

Since ancient times, mankind has been trying to combine the strength of steel with the non-corrosive properties of copper. In 1915, that idea became a reality. Copperweld® engineers discovered a molten-weld process for permanently bonding copper to steel. Ever since, their company has been considered the leader in innovation in the bimetallic industry. The original process was replaced by a solid cladding process in 1979.

Genuine Copperweld® Copper-Clad Steel (CCS) wire and strand have been utilized and relied upon for over 90 years as strong, non-corrosive, efficient grounding conductors. Combining the strength of steel with the conductivity and corrosion resistance of copper, Copperweld® provides a long-lasting, low impedance path to earth.

Copperweld® delivers outstanding reliability and performance in a variety of applications at every step in the power utility process: generation, transmission, and distribution of current.

Why choose copperweld?

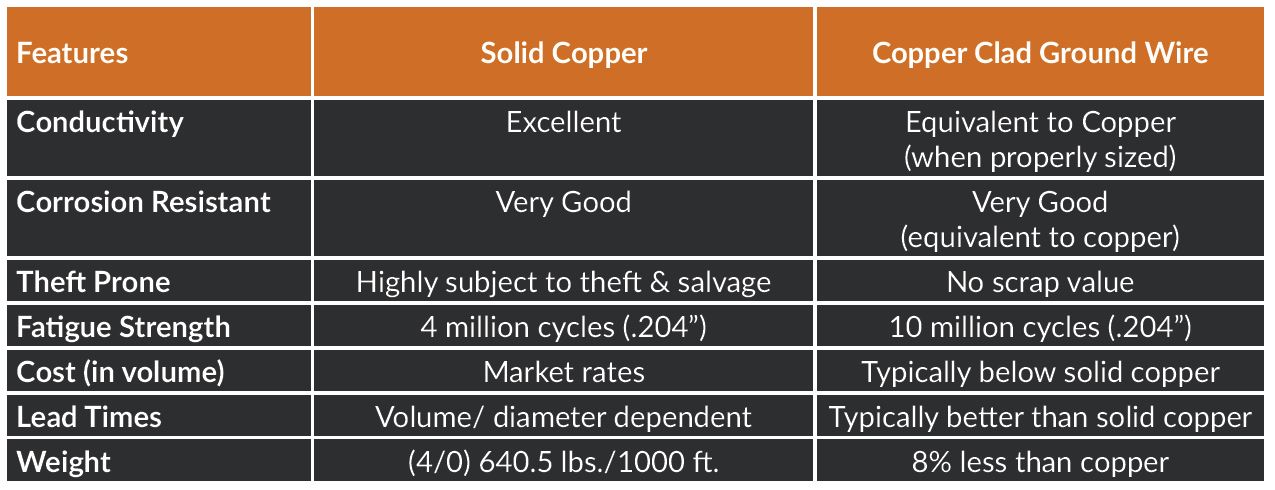

Advantages of choosing copper clad steel over pure copper wire:

- Theft deterrent

- Greater fatigue life – lasts longer

- Excellent current carrying capability (skin effect)

- Lower cost than copper

- Lighter weight than copper

- Installs the same as copper

- Improves safety management

Copperweld® wire is less susceptible to theft than solid copper because it is a bimetallic product and does not have the high scrap value of pure copper. The copper layer in our Copperweld® CCS cannot be removed, and so it is practically worthless to would-be black marketers.

copperweld® camo™

Copperweld® CCS is also available in camo colours, providing additional features for deterring theft:

Looks like steel

Utilizes same connectors as copper, no stripping required

Lowest cost grounding conductor (copper)

No galvanic corrosion

Ample fault current capacity

Is magnetic, deterring scrap dealers

Copperweld® hide™

Replace solid copper with Copperweld® Hide™, Copper Clad Steel (CCS) ground wire to reduce theft.

- 95% of electric utilities have copper theft costing over 60 million dollars in a year

- Utilities experience 450,000 minutes of outage time a year

- These issues result in an estimated 52 injuries and 35 deaths a year

- Copper price increases are not predictable

Copperweld® Hide™ is coated with a lead free, flame retardant poly jacket providing excellent ultraviolet resistance and long life.

Easy-strip coating makes installation fast and simple

Clean copper surface requires no wire brushing

Installs as easy as copper- dead soft annealed

CCS- PHYSICALLY STRONGER THAN COPPER

Copper clad steel actually performs better on the fatigue tests than pure copper wire.

ASTM B-193, ASTM B-452, ASTM B-227, ASTM B-228 and ASTM B-910 certified

RUS (Rural Utilities Service) listed

All bimetallic products are processed at the Copperweld®’s ISO9001 and ISO14001 certified facility in Fayetteville, TN

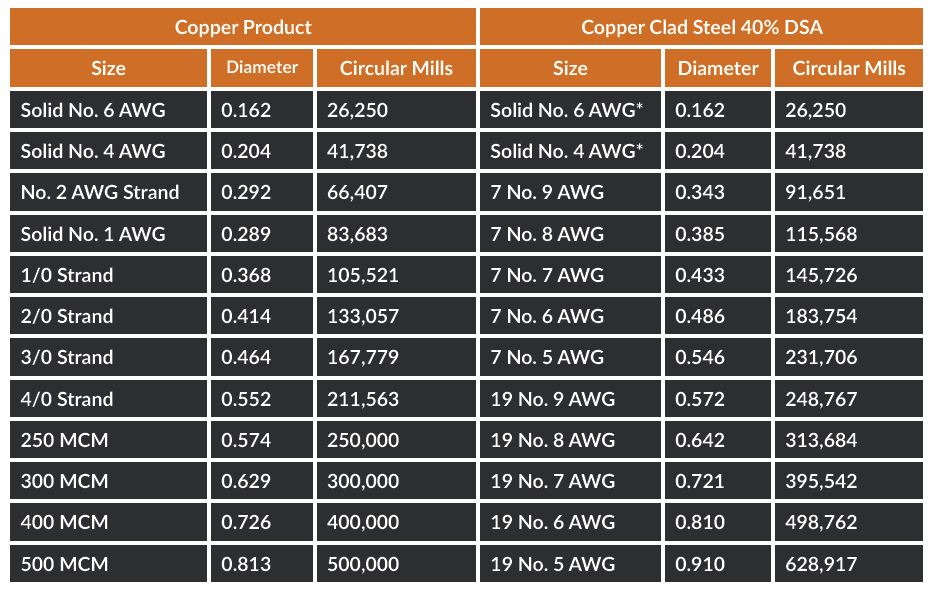

PROPER PRODUCT SIZING FOR COPPER CLAD STEEL GROUNDING APPLICATIONS

PHYSICAL AND ELECTRICAL PROPERTIES

To learn more about this vendor click here to visit their website!

For price, delivery, product demo or other questions click here!